Chicago Additive Update – AMOS Product Line & Company News

It’s time for an update on the AMOS product line and everything happening behind the scenes at Chicago Additive. While it’s taken longer than expected to roll out updates, we’re excited to share that moving forward, we’ll be providing:

Monthly Deep Dive Updates – first week of each month

Progress Updates – third week of each month

This ensures consistent communication and transparency as we continue building momentum.

📑 Documentation

We’re making AMOS support resources easier to access:

Documentation and guides are moving to a public Wiki (no password required).

This Wiki will serve as a living document, updated continuously.

Offline documentation will be available upon request as a binder or printable PDF.

A change log will track updates, with quarterly summaries for clarity.

⚙️ Production Updates

AMOS 300 – In full production and shipping now, available in both 1.75mm and 2.85mm filament versions. Accessories, cases, and upgrades are now listed on chicagoadd.com.

AMOS 500 – Production underway, with shipping set to begin September 1st.

AMOS 200 – In final pre-production stages, with shipments expected in October.

🧪 Testing & Development

Chamber heaters – in final software tuning; all AMOS units are hardware-ready for plug-and-play upgrades.

Profile tuning in progress for multiple materials in Cura and PrusaSlicer:

ABS GF

ABS CF

PA12 CF

PPS CF

Lightweight ASA

Lightweight PLA

🏛 Company Update

We’re proud to announce that Chicago Additive has officially joined America Makes, the nation’s leading public-private partnership for additive manufacturing. This aligns us with a powerful network advancing U.S. competitiveness in AM technology.

📅 Upcoming Events

Our team will be attending the following:

🚀 Thank you to everyone supporting the AMOS line and Chicago Additive. We’re looking forward to keeping you updated with more frequent and detailed progress moving forward.

AMOS Press Release

Chicago Additive Secures Navy Co-Exclusive License for Key Additive Manufacturing Patent, Launches AMOS Line of 3D Printers

May 19, 2025 – Chicago Additive is proud to announce that it has been granted a Co-Exclusive License for U.S. Patent Application 18/926770, titled “Advanced Manufacturing Operational Apparatus, System, and Method.” This milestone underscores our commitment to driving innovation in the additive manufacturing space.

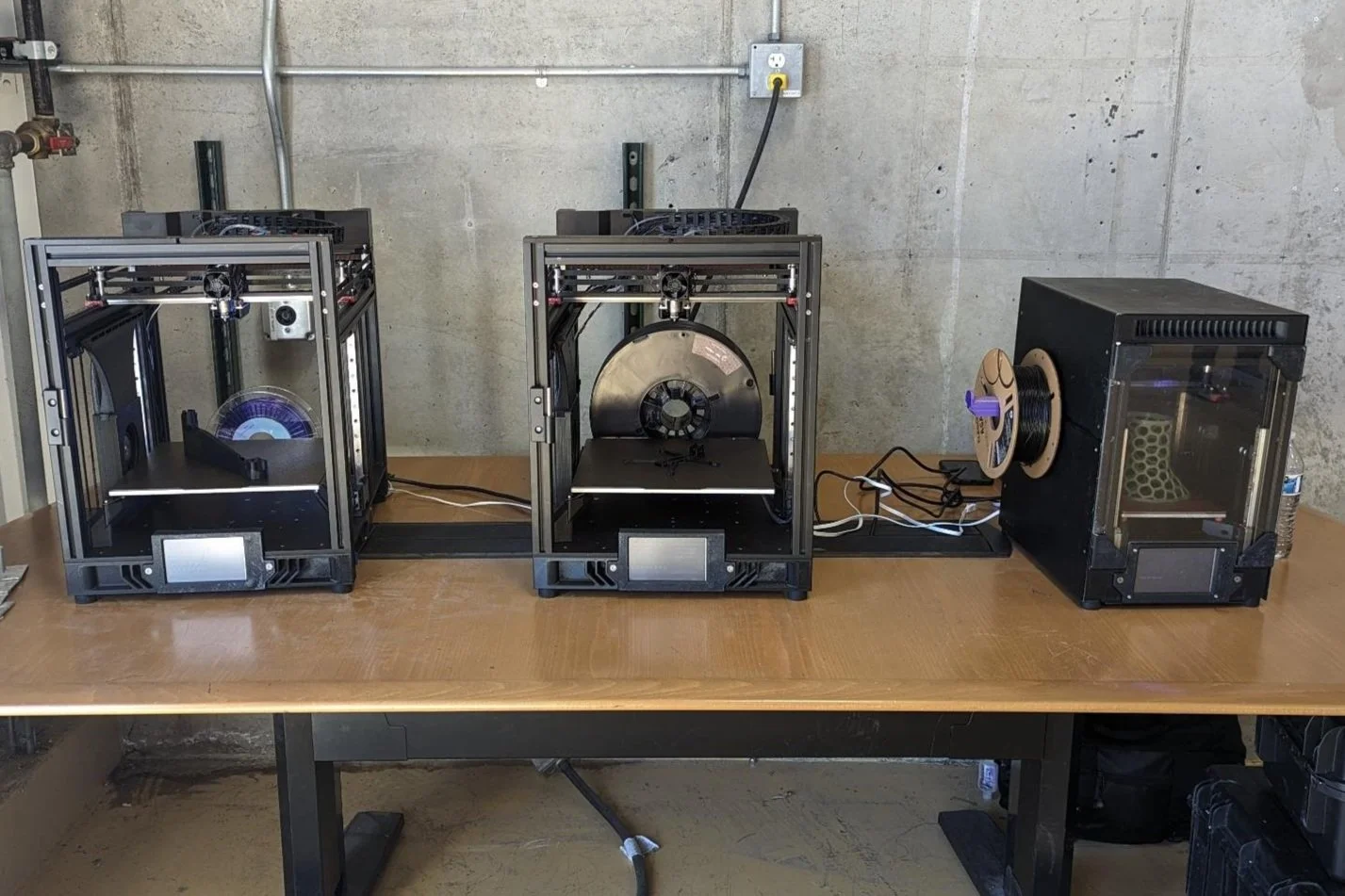

In partnership with inventor Spencer Koroly and his team at the Naval Information Warfare Center Pacific (NIWC Pacific)—a federal research laboratory operated by the U.S. Navy in San Diego—Chicago Additive has played a key role in the development, testing, and production of pre-release units of the AMOS 3D printer line. This collaboration enabled the establishment of a dedicated production facility, featuring streamlined manufacturing processes and a purpose-built assembly line specifically for the AMOS printers.

AMOS PRODUCTION HAS BEGUN

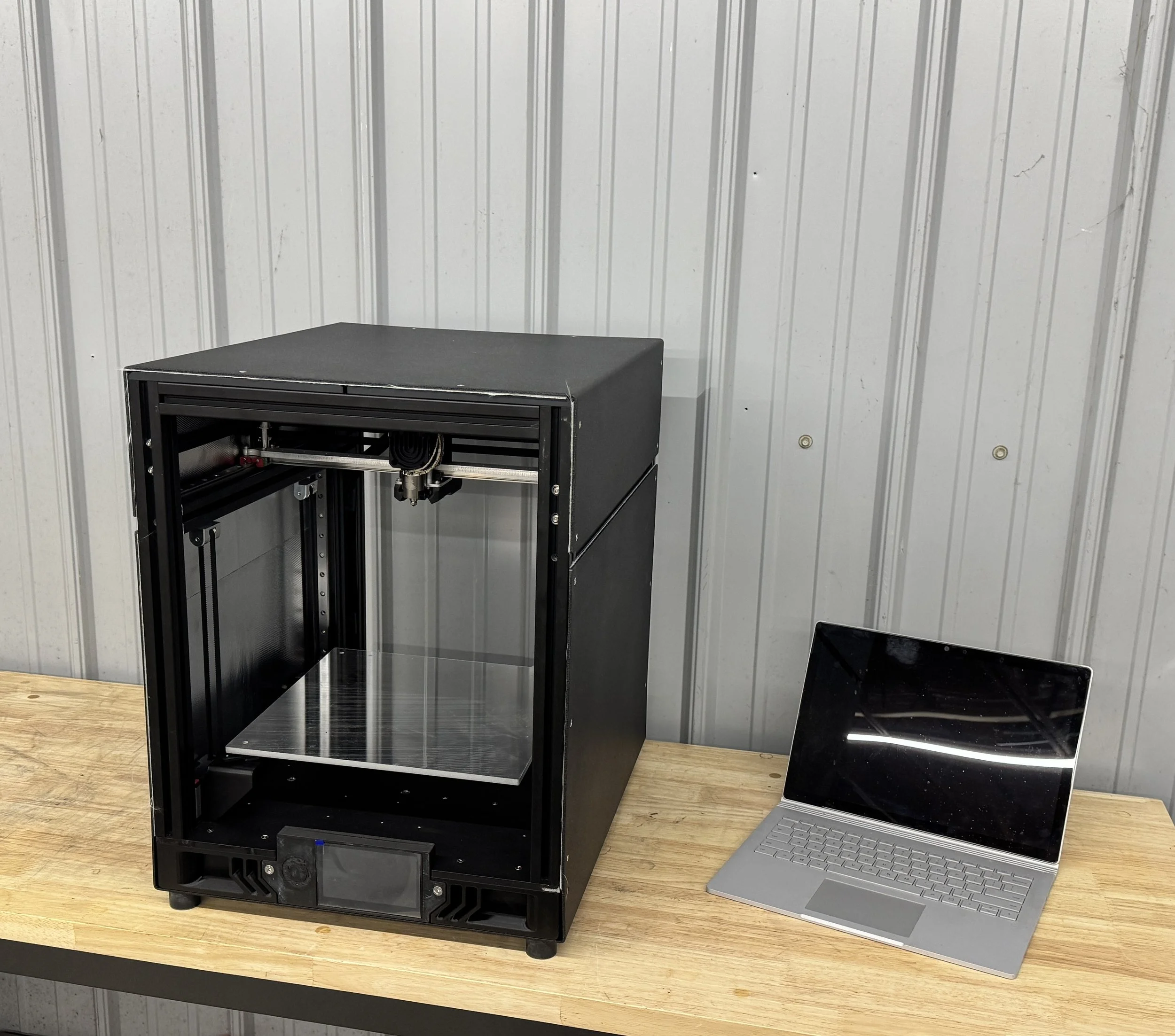

With infrastructure and operations already in place, Chicago Additive has begun production of the AMOS 300, with initial units scheduled to ship by the end of Q2 2025. Additional models, the AMOS 200 and AMOS 500, are slated for release in Q3 2025.

The AMOS line is redefining desktop additive manufacturing for the U.S. military and allied partners. These printers are engineered for high-quality output, ease of maintenance, and secure operation, making them ideal for industrial users, educational institutions, and print farms. Every unit can be configured to meet strict security requirements, ensuring data integrity with no information ever leaving the hardware.

Common Features Across the AMOS Line:

High-speed printing (250-500 mm/s)

Core-XY motion system with premium belts, pulleys, idlers, and linear rails

Fully enclosed, ruggedized enclosures for durability

Internal filament storage for material integrity

Advanced motion controller developed by UK partner

Integrated humidity control for optimal printing conditions

Optional active chamber heating for high-performance materials

Model-Specific Features:

AMOS 200

Build Volume: 200 × 200 × 120 mm (XYZ)

Optional transport case compatible with carry-on luggage

AMOS 300

Build Volume: 300 × 300 × 220 mm (XYZ)

Rack-mountable: fits up to 3 printers per standard server rack (or 2 with battery backups)

Optional ruggedized case for travel and in-transit printing capabilities

AMOS 500

Build Volume: 500 × 500 × 420 mm (XYZ)

Optional mobility casters

Optional stand for added stability

Over the next two weeks, initial production units will be shipped to select testers for final validation of packaging, print profiles, and user experience. We will begin accepting orders during this period, with fulfillment beginning in the first week of June 2025. Regular updates will follow as we ramp up production and deployment.

We extend our sincere thanks to NIWC Pacific and the TechLink Center for their support and partnership throughout this process—it has been a privilege to work alongside such dedicated teams.

Quote From the Team

“After 19 months of collaboration with Spencer, we’re ready to put the AMOS into the hands of those who need it,” said Joseph Podogrski. “I want to thank everyone at NIWC Pacific who helped shape the AMOS into what it is today, as well as the tech transition team for making the licensing process as smooth as possible.”

Please follow along with our update on our website or social media found here:

Website: https://www.chicagoadd.com/

Updates Page: https://www.chicagoadd.com/learn

X (Twitter): https://x.com/ChicagoAdditive

BlueSky: https://bsky.app/profile/chicagoadditive.bsky.social

About Chicago Additive

Founded in 2024, Chicago Additive was established to unite industry-leading experts in additive manufacturing to solve the sector’s most pressing challenges. Since our inception, we have operated behind the scenes, collaborating with OEMs and supporting institutions like NIWC Pacific through development and manufacturing services.

Our mission is to equip the military, education sector, and industry with robust, U.S.-designed and manufactured tools to meet tomorrow’s demands. Our team brings together world-class talent in design, mechanical, and electrical engineering, each member with over a decade of hands-on experience in additive manufacturing.

We operate two facilities in Demotte, located in Northwest Indiana, one of which is exclusively dedicated to the production of the AMOS line of 3D printers, with a current production capacity of 2,500 units per year.

Notes To Editors

Media assets can be found here: https://drive.google.com/drive/folders/178gzWJaIyxB40sRsmW0Q11iU5u9r3oki?usp=sharing

Or contact cateam@chicagoadd.com

Posts about the AMOS during development:

High Speed Benchy Test Print Video- https://www.linkedin.com/posts/spencer-koroly-86673282_3dprinting-advancedmanufacturing-activity-7260747129227288576-_ukr?utm_source=share&utm_medium=member_desktop&rcm=ACoAADe0ANkBuW2vC9oN1NRB2CKNG2MATk-mISg

Podcast discussing the AMOS and development- https://www.linkedin.com/posts/navwar_next-level-podcast-episode-3-activity-7260447590922559489-1khy?utm_source=share&utm_medium=member_desktop&rcm=ACoAADe0ANkBuW2vC9oN1NRB2CKNG2MATk-mISg

Articles about the AMOS throughout development and testing:

Marines demonstrate in-flight 3D printing aboard a U.S. Marine Corps aircraft. By Kety S https://3dadept.com/marines-demonstrate-in-flight-3d-printing-aboard-a-u-s-marine-corps-aircraft/

RIMPAC exercise tests bounds of 3D printing of crucial parts in real time. by WYATT OLSON (Chicago Additive build units deployed to Hawaii for the Rim of the Pacific exercise) https://www.stripes.com/theaters/asia_pacific/2024-07-05/rimpac-3-d-printing-navy-hawaii-14398425.html

For media inquiries, please contact our team at:

Equipping startups with the tools to take on Goliaths

Chicago Additive was founded in 2024, drawing on the expertise of a diverse team from the additive manufacturing sector. Our mission is to provide comprehensive hardware solutions, small batch production services, and consulting expertise tailored to meet the needs of small businesses, industrial clients, and governmental organizations.

Our consulting offerings include specialized services such as Additive Implementation and Hardware Design. In 2021, a valued member of our team, Joe, began a consulting engagement with a filament manufacturer transitioning into the hardware market. At the outset, this organization had already designed and sourced components for their inaugural commercial hardware release. Upon Joe's involvement, he focused on establishing a streamlined assembly line for rapid production. Within a month, we achieved a significant reduction in production time, decreasing the unit turnaround from weeks to mere days by implementing the appropriate equipment and assembly processes. Over the subsequent two months, Joe's expertise extended to refining design elements to align with “design for manufacturing” standards, thus enhancing overall production efficiency.

Following the completion of the initial project, Joe was invited to continue collaborating with the client, transitioning his role from production and design consulting to hardware design and implementation. The client had secured a contract to develop specific hardware solutions tailored to their own clients' needs. Joe leveraged his collaborative skills, working closely with the client's mechanical and electrical engineering teams to conceptualize a distinctive hardware platform, successfully completing the design in two months and the production in three weeks.

One of Joe's contributions was the design of a pioneering XY/Hybrid Motion System capable of accommodating up to three tool heads, enabling a versatile combination of standard filament and pellet extrusion. Following the hardware production phase, Joe shifted his focus to implementation, traveling to the client's location to oversee installation, setup, and staff training. Over the course of the next month, Joe played a crucial role in integrating the new hardware into the client's existing workflows.

Currently, Joe leads the Chicago Additive Consulting Team. Should you have any inquiries or require assistance, please do not hesitate to reach out to us. Our team is eager to support you in harnessing the power of additive manufacturing to enhance your production capabilities.